In recent years, the Hydraulic Cooling System industry has witnessed remarkable innovations. According to a report by Market Research Future, the market for hydraulic cooling systems is expected to grow by over 5% annually until 2026. This growth is driven by advancements in technology and an increasing demand for efficient cooling solutions in various sectors.

Dr. Amelia Johnson, a leading expert in hydraulic systems, emphasizes, "Innovation in hydraulic cooling systems is essential for improving efficiency and reducing energy consumption." These systems are crucial in industries like construction, automotive, and manufacturing, where maintaining optimal temperatures can significantly impact performance.

Yet, challenges remain. Many companies still rely on outdated cooling methods, which can lead to inefficiencies. There is a growing need for industry players to evaluate their current systems and adapt to new technologies. As we explore the innovations in hydraulic cooling systems, we must consider both their potential and the areas needing improvement.

As we approach 2026, hydraulic cooling systems are evolving rapidly. Emerging technologies are reshaping how industries maintain optimal operating temperatures. Advanced materials, such as graphene composites, promise improved heat dissipation. According to a recent report, incorporating these materials can enhance thermal conductivity by up to 50%. This innovation allows for more compact designs, making systems lighter and more efficient.

Emerging trends also highlight the integration of machine learning. Predictive maintenance is becoming crucial. For example, sensors can analyze temperature data, predicting failures before they occur. This proactive approach can reduce downtime by 30%, according to industry analysts. However, the challenge lies in ensuring data accuracy. Some companies struggle with the vast amounts of data generated.

Moreover, the push for sustainability drives innovation. Energy-efficient designs can greatly reduce operational costs. Recent studies show that optimizing hydraulic cooling can cut energy usage by nearly 20%. Yet, some systems still consume excessive power. Striking a balance between efficiency and performance remains complex. The industry must address these concerns for future growth.

| Innovation | Application Area | Key Features | Expected Impact |

|---|---|---|---|

| Advanced Heat Exchangers | Industrial Machinery | Enhanced thermal efficiency | Increased energy savings |

| Smart Control Systems | Automotive | Real-time monitoring and adjustments | Improved system reliability |

| Eco-Friendly Coolants | Construction Equipment | Non-toxic and biodegradable | Reduced environmental impact |

| Compact Cooling Solutions | Aerospace | Space-saving designs | Enhanced design flexibility |

| Predictive Maintenance Tools | Marine Systems | Data analytics for maintenance | Increased uptime |

In recent years, innovations in materials have significantly enhanced the efficiency of hydraulic cooling systems. Advanced polymers and composite materials provide better thermal conductivity. These new materials also offer increased durability, resisting corrosion and wear over time. Improved heat dissipation is crucial for optimal performance in various applications.

Thermal interface materials (TIMs) have garnered attention. They fill gaps between surfaces, enhancing heat flow. Improved TIMs can reduce thermal resistance, leading to better cooling. However, the challenge remains in finding the right balance between conductivity and mechanical strength. Many options exist, but not all perform consistently under stress.

Moreover, lightweight materials play a vital role. They reduce the overall weight of hydraulic systems. This can lead to lower energy consumption and improved efficiency. However, some lightweight options may compromise strength. Designers must evaluate the trade-offs carefully. Choosing the right materials is not just a technical decision; it affects performance and longevity.

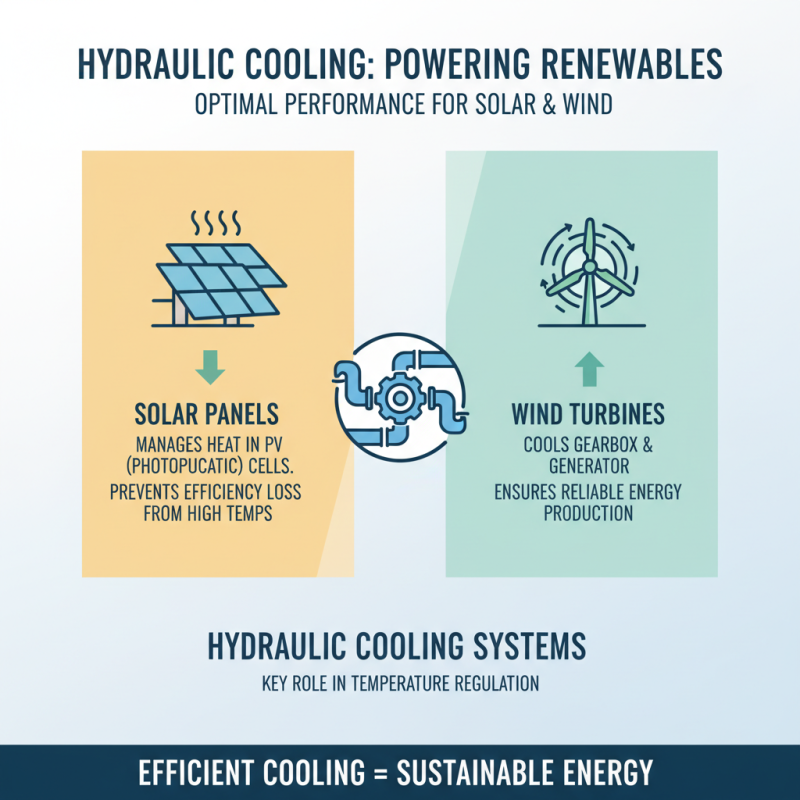

Hydraulic cooling systems play a critical role in renewable energy sectors. These systems manage heat in solar panels and wind turbines. Efficient cooling helps maintain optimal performance. When temperatures rise, performance can degrade. So, effective cooling is essential for energy production.

In solar farms, hydraulic cooling manages the heat generated by panels. Excess heat can reduce efficiency. A well-designed cooling system ensures panels operate at peak levels. Similarly, in wind energy, turbines generate heat during operation. Hydraulic systems help dissipate this heat quickly. This minimizes wear and tear on equipment.

However, there are challenges to overcome. Installation of these systems can be complex. Maintenance requires skilled personnel. In some cases, cooling efficiency may not meet expectations. Continuous research is needed to improve these systems. Innovations must address flaws and boost reliability.

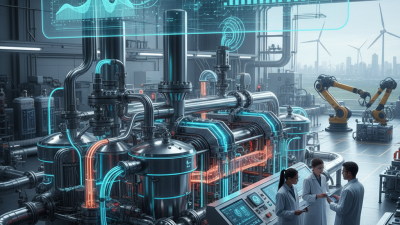

The evolution of hydraulic cooling systems has sparked significant interest in their applications. Traditional systems often rely on water and air to dissipate heat. They are simple but can fall short in performance. Reports indicate that these systems are becoming less efficient. They typically struggle in high-pressure operations, leading to risks of overheating.

In contrast, innovations feature advanced materials and designs. For instance, a report from the Hydraulic Institute highlights that innovative systems can reduce energy consumption by up to 30%. These systems often incorporate smart technologies for real-time monitoring. This can radically improve efficiency, but challenges remain. Not all sectors have adopted these advanced solutions, leading to inconsistent performance across industries.

Moreover, while new technologies promise enhanced cooling, they require careful implementation. Overlooking compatibility with existing systems can lead to failures. Workforce training is also essential, yet often neglected. Engineers must adapt quickly to new methodologies. Their reluctance can hinder the full potential of these innovations. This space is ripe for exploration and improvement, as gaps in understanding continue to exist.

The hydraulic cooling system landscape is evolving rapidly. Recent reports indicate a potential growth rate of 7% annually in this sector. However, challenges exist. The increasing demand for energy efficiency pushes manufacturers to innovate. Solutions must balance performance and cost.

New materials are becoming popular for heat exchange, improving thermal conductivity. Yet, their durability remains questionable. For instance, a study showed that certain lightweight alloys could degrade under extreme conditions. The quest for eco-friendly solutions also presents complexities. Biodegradable fluids may not perform well in all scenarios, raising concerns over their longevity and reliability.

Investment in research is essential. Recent data shows that R&D spending in hydraulic systems is projected to exceed $2 billion by 2025. Companies must focus on improving flexibility in design. The integration of smart technology presents promising opportunities but also requires careful consideration. User adaptability and the skill gap pose risks for widespread implementation. The path forward is fraught with obstacles, necessitating ongoing dialogue and innovation.