Choosing the right Microchannel Heat Exchanger can seem daunting. Renowned industry expert Dr. Emily Carter states, "Understanding your unique requirements is key to selecting an efficient microchannel solution." Her insight underscores the importance of customization in this intricate field.

Microchannel Heat Exchangers offer exceptional thermal performance and compact size. However, not all models suit every application. Factors like fluid properties, pressure drops, and ambient conditions play critical roles. It's about balancing efficiency and cost.

Yet, many may overlook these details. Relying solely on general specifications can lead to suboptimal choices. It's vital to reflect on specific needs and constraints. Each application is different, and what works for one may not for another. Consider consulting with experts to navigate this complex landscape.

Microchannel heat exchangers are compact devices that enhance thermal management in various applications. They are often used in HVAC systems, refrigeration, and industrial processes. Their design allows for efficient heat transfer due to a large surface area and small fluid volume. Understanding their structure is crucial when selecting the right unit for your needs.

When choosing a microchannel heat exchanger, consider the specific application. Will it be used in a high-temperature environment? What type of fluid will flow through? These factors influence the heat exchanger's material and design. You might find that a finned configuration suits some applications better than others.

Tips: Always check the compatibility of materials with your working fluids. Pay attention to pressure drop requirements. A higher pressure drop may indicate a need for redesign or a different configuration.

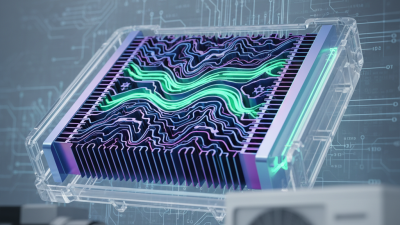

Microchannel technology can be challenging. You may find it difficult to get precise measurements. Testing is essential to ensure efficiency. If the data is off, it can affect the overall performance. Getting feedback from engineers or using simulation software can help refine your choices.

Selecting the right microchannel heat exchanger can be daunting. Multiple factors play a crucial role in your decision. Efficiency is paramount. High-efficiency models can significantly reduce energy consumption. Look for units that feature optimized flow paths. The design needs to match your application’s specific thermal requirements.

Material compatibility is essential. The exchanger must endure the working environment. Corrosion-resistant materials increase longevity. Assess the fluids involved, as certain materials react poorly to specific chemicals. Don't overlook maintenance needs. Some designs are easier to service than others.

Tip: Always check the manufacturer's specifications. This can help avoid mismatched performance expectations. Consider the size of the unit, too. Ensure it fits into your designated space. Performance is not the only concern. A unit that fits poorly can lead to inefficiencies.

Another point to reflect on is cost. Sometimes, the cheapest unit isn’t the best choice. Investing in quality may yield better returns. Weigh immediate savings against long-term gains.

| Factor | Description | Considerations |

|---|---|---|

| Capacity | The heat exchanger's ability to transfer a specific amount of thermal energy. | Assess your system requirements and peak load conditions. |

| Size and Footprint | Physical dimensions of the heat exchanger and installation space. | Ensure compatibility with existing systems and available space. |

| Material | The type of materials used in construction, determining durability and corrosion resistance. | Choose materials based on application environment and fluid compatibility. |

| Pressure Drop | The loss of pressure occurring as fluids flow through the heat exchanger. | Minimize pressure drop to maintain system efficiency. |

| Cost | Overall price including purchase, installation, and maintenance costs. | Balance upfront costs with long-term operational efficiency. |

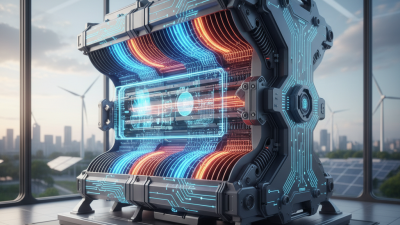

When choosing a microchannel heat exchanger, understanding thermal and fluid flow performance is crucial. Start by evaluating the heat transfer effectiveness. This often dictates the overall efficiency. Look for specific metrics, such as the overall heat transfer coefficient. A higher coefficient signifies better performance under given conditions. However, this might not always translate to your precise needs.

Fluid flow characteristics also play a significant role. Assess the flow rates required for your application. Ensure the heat exchanger can handle the desired velocities without creating excessive pressure drops. These drops can lead to inefficiencies. Remember, an overly aggressive design might complicate maintenance. Balancing performance and ease of use is essential.

While focusing on specifications is important, don’t overlook real-world applications. Field tests often reveal nuances that data alone cannot capture. It's wise to consult with engineers or industry experts. Their insights can help identify potential pitfalls. Avoid relying solely on theoretical models. They might obscure practical challenges in fluid dynamics or thermal efficiency.

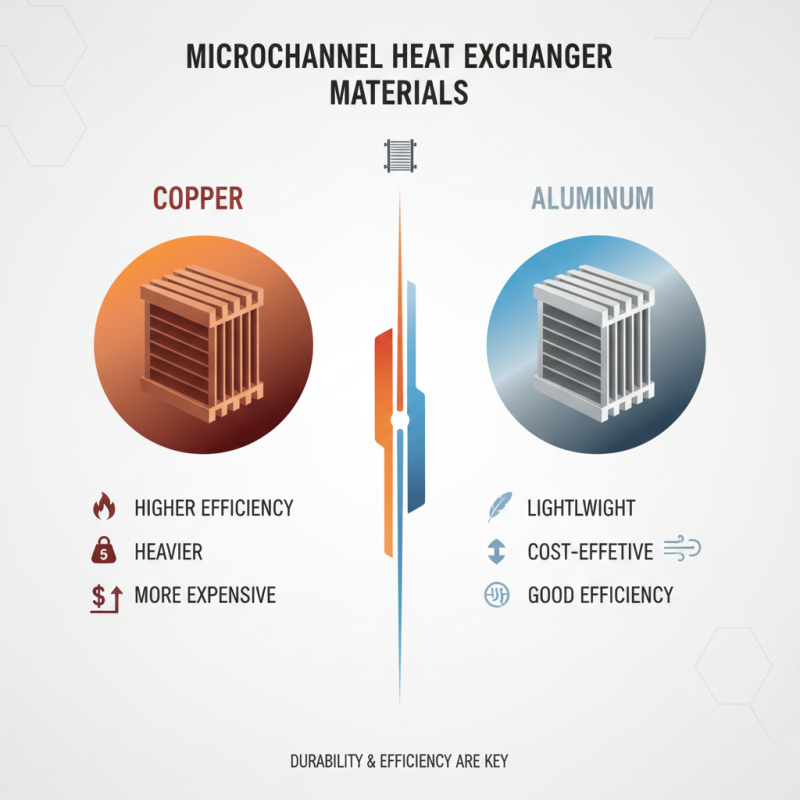

Selecting the right material for microchannel heat exchangers is crucial. It impacts both durability and efficiency. According to industry reports, copper and aluminum are commonly used due to their excellent thermal conductivity. Copper is more efficient, but it's heavier and more expensive. Aluminum is lightweight and often favored for its cost-effectiveness.

However, the choice isn’t simple. Environmental factors play a significant role. For instance, in corrosive environments, stainless steel could be a better option despite its lower thermal performance. This material offers durability in challenging conditions, which can lead to longer service life.

Certain studies indicate that choosing the wrong material could lead to a decrease in performance by up to 30%. This loss is often overlooked. Some users may focus only on initial costs instead of long-term efficiency. Reflecting on material decisions is essential. Given the complexity of heat transfer, selecting the appropriate material is vital for optimizing system performance.

When selecting a microchannel heat exchanger, cost plays a pivotal role. Microchannel technology can offer better efficiency, but the initial investment may be high. You might wonder if the expense justifies the return. It's essential to evaluate your specific heating and cooling needs against your budget constraints. Factor in both purchase price and operational costs. Cheaper options often lead to higher maintenance fees later. Investing wisely from the start could save money down the line.

Consider installation costs as well. These can add significant figures to your overall expenditure. Do you have the right tools and expertise in-house? Hiring outside help can inflate costs quickly. Additionally, remember the potential for future adjustments and capacity needs. Oversizing can lead to wasted energy and higher bills. Undersizing can mean a constant battle with inefficiency. This balancing act requires careful planning.

Reflect on your long-term goals. Are you looking to expand or change your process shortly? Flexibility in your heat exchanger choice could save you from future headaches. Revisiting these aspects during budgeting helps avoid uninformed decisions. Identifying the right balance between upfront costs and long-term value is crucial. Your choices today will impact your financial health tomorrow.