Choosing the right Microchannel Heat Exchanger can be challenging. There are many factors to consider. These compact systems play a crucial role in modern cooling and heating applications.

Microchannel Heat Exchangers are different from traditional exchangers. Their design allows for more efficient heat transfer. This results in smaller, lighter units. They save space and energy. However, not all microchannel designs suit every application.

It's essential to evaluate your specific needs. Consider factors like fluid types, flow rates, and pressure drops. A mismatch can lead to performance issues. You may end up with inefficiencies. A detailed analysis will help ensure you select the right system for your requirements.

Microchannel heat exchangers are compact devices. They play a crucial role in transferring heat efficiently. Generally, they consist of multiple small channels. This design enables higher heat transfer rates compared to traditional exchangers. According to industry reports, microchannels can improve energy efficiency by up to 50%. These devices are commonly used in HVAC systems, refrigeration, and automotive applications.

Choosing the right microchannel heat exchanger requires understanding your specific needs. Consider factors such as flow rates, pressure drops, and temperature differences. These parameters greatly influence overall performance. It's essential to match the exchanger design with your application demands. Incorrect sizing can lead to inefficiencies or failures.

Tips: Always consult performance curves before making a selection. Review system requirements thoroughly. Testing under real conditions can provide valuable insights into potential issues. Be aware that the manufacturing process and materials can also impact lifespan and performance. Microchannel heat exchangers can offer significant benefits, but careful evaluation is vital for achieving optimal results.

Choosing the right microchannel heat exchanger is essential for efficiency and performance. Key factors significantly influence the selection process. These factors include heat transfer efficiency, compatibility with fluids, and space constraints. According to industry reports, microchannel heat exchangers can improve heat transfer rates by up to 50% compared to traditional designs. This makes them ideal for applications requiring compact solutions.

Consider fluid compatibility. Using the wrong material can lead to corrosion or efficiency loss. Pay attention to the working pressures and temperatures. Opt for materials that align with the operational conditions. Also, look at the heat exchanger’s design—some are optimized for particular applications, like automotive or HVAC systems. Understanding the specific requirements of your project is crucial in achieving optimal performance.

Tip: Evaluate your space. Microchannel designs are compact but still need proper clearance for maintenance. Choose a model that fits your environment without sacrificing performance.

Review your project needs continuously. Sometimes, a more cost-effective solution underperforms in the long run. This compromises efficiency and increases energy costs. Take the time for a thorough analysis before making a decision. A well-informed choice leads to lasting benefits.

Microchannel heat exchangers have gained popularity in various industries. They offer significant advantages over traditional heat exchangers. Their compact size allows for a reduced footprint in equipment design. This can be a game-changer for systems with space limitations. However, their complexity might require more careful handling during installation.

In contrast, traditional heat exchangers tend to be larger and simpler. They are often easier to maintain. Yet, they consume more energy and may not be as efficient as microchannel designs. The difference in heat transfer rates between the two can be significant. Microchannels typically provide higher efficiency, especially in cooling applications. But the initial cost can be higher, and this needs careful consideration.

Choosing between these options depends on specific needs. Factors like size, efficiency, and budget play a critical role. Understanding your application is vital. Many might overlook the ongoing maintenance costs associated with each type. Reflecting on these aspects can lead to more informed decisions. Choosing the right heat exchanger should be based on comprehensive evaluation rather than just initial impressions.

| Feature | Microchannel Heat Exchanger | Traditional Heat Exchanger |

|---|---|---|

| Heat Transfer Efficiency | High | Moderate |

| Size and Weight | Compact and Lightweight | Bulkier |

| Manufacturing Cost | Higher | Lower |

| Pressure Drop | Lower | Higher |

| Application Versatility | High | Moderate |

| Maintenance Requirement | Lower | Higher |

Microchannel heat exchangers shine in several application scenarios. They are compact and efficient. Such units are ideal for the HVAC industry. Their small size allows for easy integration into tight spaces. In heat recovery systems, their performance is impressive. High heat transfer rates mean more energy savings.

In automotive applications, these heat exchangers cool engines effectively. They respond quickly to changing temperatures. However, installation can present challenges. Proper alignment and sealing are crucial for optimal performance. Neglecting these factors might lead to failures down the line.

In refrigeration systems, efficiency is key. Microchannel designs reduce refrigerant charge and enhance system reliability. Yet, maintenance requires attention. Small components can be prone to clogging. Regular checks can prevent major issues. Finding the right balance in application is essential for success.

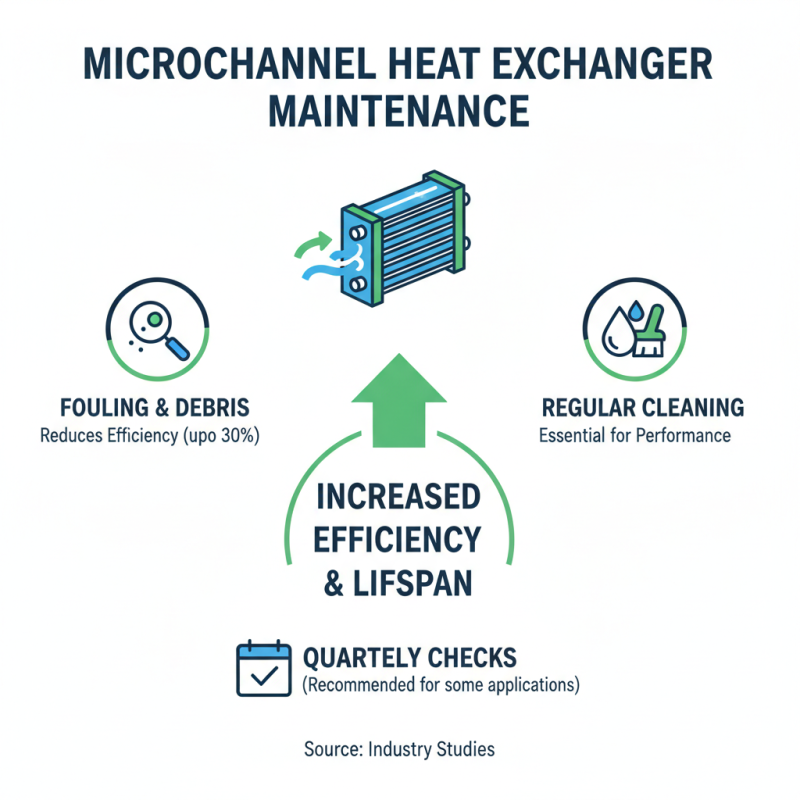

Microchannel heat exchangers (MCHEs) offer efficiency but come with unique maintenance needs. They can be sensitive to fouling and debris accumulation. Regular cleaning is essential. It’s worth noting that industry studies show that fouling can reduce efficiency by up to 30%. Cleaning intervals depend on the application and environment. In some scenarios, quarterly checks might be necessary.

Another aspect is fluid management. The correct type and quality of working fluids affect performance. According to a 2021 report, maintaining optimal fluid flow can enhance heat transfer efficiency significantly. However, improper fluid choice may lead to corrosion or blockages. Regularly monitoring fluid properties is vital for operational longevity.

Lastly, installation plays a crucial role. MCHEs must align properly with systems to avoid stress and misalignment. Issues during installation can lead to operational failures. In one case, improper alignment caused a 15% drop in efficiency. Therefore, attention to detail during installation cannot be overstated, and it reflects the importance of technical training. Each of these maintenance considerations is critical for sustaining the performance of microchannel heat exchangers.