In the pursuit of enhancing vehicle performance, selecting the right Oil Cooler for Torque Converter systems is crucial. According to Dr. Alex Thompson, a renowned automotive cooling systems expert, “The efficiency of a torque converter can significantly be improved by implementing a high-quality oil cooler that ensures optimal temperature management.” As engines generate heat during operation, managing this heat effectively can prevent overheating and prolong the life of your vehicle's components, especially the torque converter.

Choosing the best oil cooler involves understanding the specific requirements of your torque converter system and evaluating various options based on design, size, and cooling capacity. An inadequate cooling solution can lead to decreased performance and potential damage, making it imperative to prioritize quality and compatibility in your selection process. With the right Oil Cooler for Torque Converter, you can achieve better fluid dynamics and ensure that your vehicle performs at its best, even under the most demanding conditions.

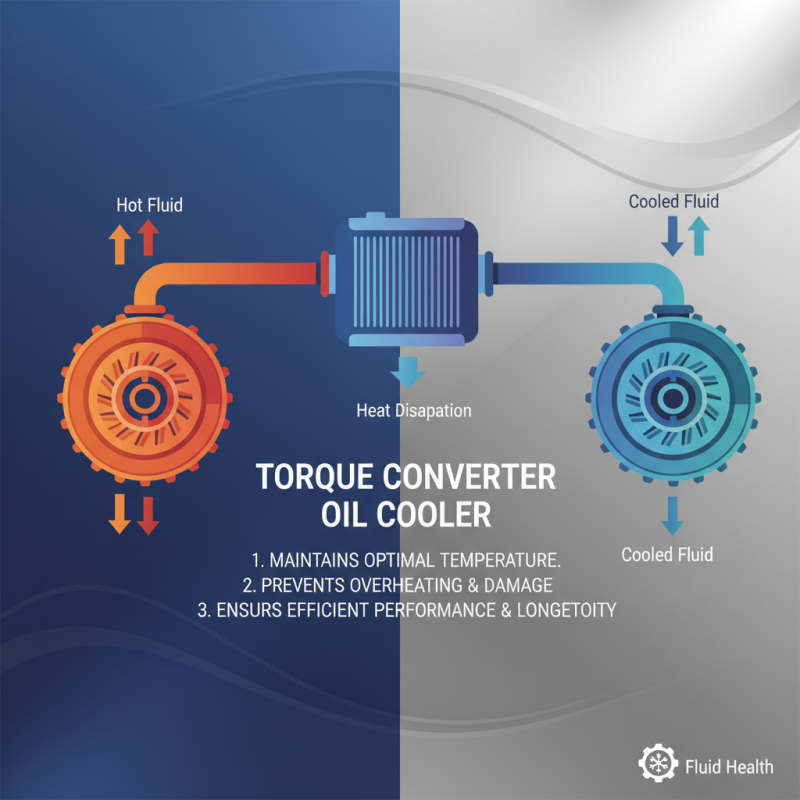

In a torque converter system, oil coolers play a crucial role in maintaining optimal operating temperatures, thereby ensuring efficient performance and longevity of the components involved. The torque converter relies on hydraulic fluid to transmit power; therefore, it's essential to keep this fluid at a stable temperature to prevent overheating. Excessive heat can lead to decreased efficiency and potential damage to the converter. An adequately designed oil cooler helps to dissipate heat from the transmission fluid, maintaining the necessary temperature balance for optimal function.

When selecting an oil cooler, consider factors such as size, flow rate, and construction material. It's vital to choose a cooler that matches your system's specifications to ensure that it can handle the volume of oil effectively. Additionally, choosing a design that facilitates easy installation can save time and reduce complications during setup.

**Tips:** Always check the compatibility of the oil cooler with your specific torque converter system before making a purchase. Also, look for coolers with superior heat exchange properties, as this can significantly impact performance efficiency in high-demand situations. Regular maintenance, including cleaning the cooler and checking for any signs of wear, can enhance its effectiveness and prolong its lifespan.

When selecting an oil cooler for your torque converter system, several key factors should be considered to ensure optimal performance and longevity. One of the primary considerations is the cooler's capacity, which is often measured in BTUs (British Thermal Units). According to industry reports, a torque converter typically generates significant heat, particularly during heavy-duty applications. It is recommended that the oil cooler can handle at least 25% more BTUs than the peak heat produced by the converter to maintain system efficiency and prevent overheating.

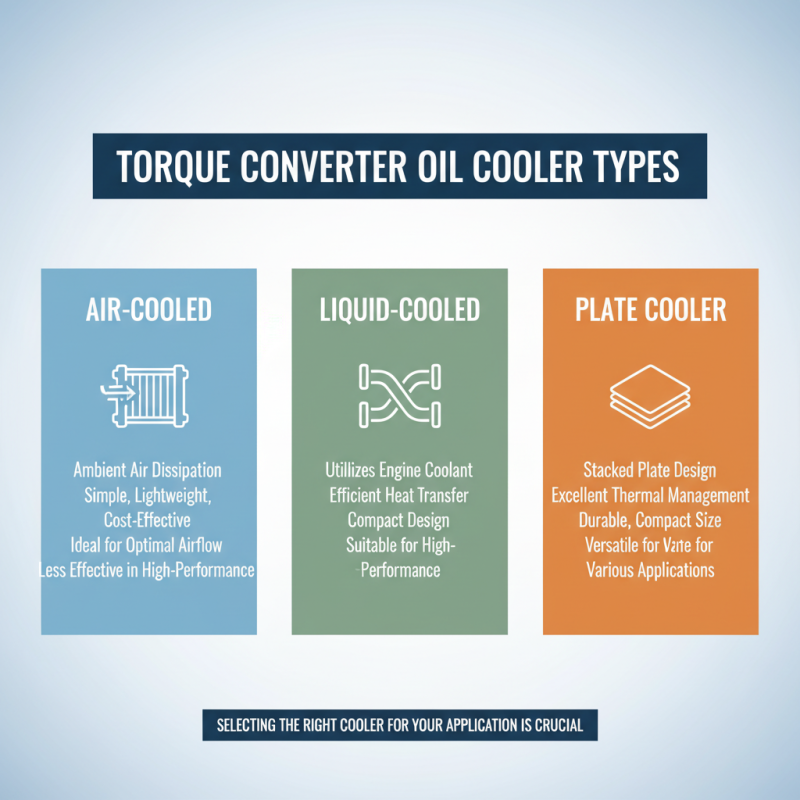

Another crucial factor is the type of oil cooler. Air-cooled and liquid-cooled options are available, each with distinct advantages. Air-cooled coolers are generally more straightforward to install and maintain but might not dissipate heat as effectively in extreme conditions. Conversely, liquid-cooled coolers offer superior thermal management, especially in high-performance setups, leading to better overall system reliability. Data indicates that systems using liquid-cooled setups can experience temperature reductions of 20-30% compared to their air-cooled counterparts.

Additionally, the material and construction of the oil cooler play a vital role in performance and durability. Aluminum coolers, for instance, are lightweight and provide efficient thermal conductivity, while steel coolers offer greater durability under harsh conditions. It's essential to choose a cooler that fits the specific demands of your vehicle and application, ensuring compatibility with existing components and ease of installation. Selecting the right cooler based on these factors can significantly enhance the performance of your torque converter system, thereby extending its lifespan and efficiency.

When selecting an oil cooler for your torque converter system, it’s essential to understand the different types of oil coolers available and how they suit various applications. The most common types include air-cooled, liquid-cooled, and plate coolers. Air-cooled oil coolers utilize ambient air to dissipate heat, making them ideal for environments where airflow is optimal. These coolers are straightforward in design, lightweight, and cost-effective, but they may not be sufficient in high-performance scenarios where thermal management is critical.

Conversely, liquid-cooled oil coolers are more efficient in managing heat, as they use coolant rather than air to regulate temperatures. These coolers can integrate easily with existing vehicle cooling systems, providing enhanced cooling performance, especially in heavy-duty applications like towing or racing. Lastly, plate coolers are compact and provide a high surface area for heat transfer, making them suitable for constrained spaces or when weight is a concern. Choosing the right type of oil cooler will depend on your specific torque converter system requirements, including performance goals, installation space, and environmental conditions.

When selecting an oil cooler for your torque converter system, compatibility is paramount. Start by examining the specifications of your existing system, including the type of fluid it uses, the operating temperatures, and the desired cooling efficiency. Ensure that the oil cooler you choose can handle the specific flow rates required by your torque converter. Mismatches in flow rates can lead to inadequate cooling, which might result in overheating and diminished performance.

Next, evaluate the physical dimensions and mounting options of the oil cooler. It’s essential that the cooler fits within the confines of your vehicle or machinery without obstructing other components. Pay attention to the inlet and outlet connections to ensure they align properly with your system.

Additionally, consider the material composition of the oil cooler; it should be durable enough to withstand high temperatures and pressure while being resistant to corrosion. Proper compatibility will not only enhance the efficiency of your torque converter system but also contribute to its longevity and reliability.

When selecting the best oil cooler for your torque converter system, installation plays a crucial role in achieving optimal performance. A well-installed oil cooler can significantly enhance the thermal efficiency of your vehicle, leading to improved transmission life and overall performance. According to the Society of Automotive Engineers, proper cooling can reduce transmission temperatures by up to 30%, which is critical in preventing overheating and ensuring longevity.

For effective installation, consider the positioning of the cooler relative to airflow. Placing the cooler in a location that maximizes airflow can lead to better cooling performance. It's advised to mount the cooler in front of the radiator or in an area where there is a consistent flow of air. Additionally, ensure that the hoses and fittings are of high quality and resistant to abrasion and heat to prevent leaks. Regularly checking the cooler for obstructions, such as dirt or debris, can also contribute to maintaining efficient operation.

Another important tip is to ensure that the oil cooler is matched to the specifications of your torque converter system. Using a cooler that is too small may not effectively reduce temperatures, while one that is excessively large can lead to operational inefficiencies. Take time to understand the cooling demands of your system and refer to data sheets that specify the appropriate cooler size based on vehicle type and usage patterns. An informed installation will not only enhance the performance of your torque converter but also extend the life of your entire transmission system.