When it comes to optimizing industrial processes, choosing the right industrial radiators is paramount. According to James Thornton, a leading expert in thermal management solutions, “The efficiency of your industrial operations hinges significantly on the performance of your radiators.” Proper selection not only enhances productivity but also plays a critical role in ensuring the longevity of equipment and machinery.

In the industrial sector, radiator technology has advanced significantly, offering diverse designs and specifications tailored to specific business needs. Factors such as heat load, fluid type, and installation environment must be carefully considered to avoid costly downtime and inefficiencies. As companies strive to meet regulatory standards and sustainability targets, understanding the nuances of industrial radiators becomes even more essential.

Ultimately, an informed decision about industrial radiators can lead to substantial operational improvements and cost savings for businesses. This guide seeks to delve deeper into the principles and considerations that will aid companies in making the right choice for lasting success in their industrial applications.

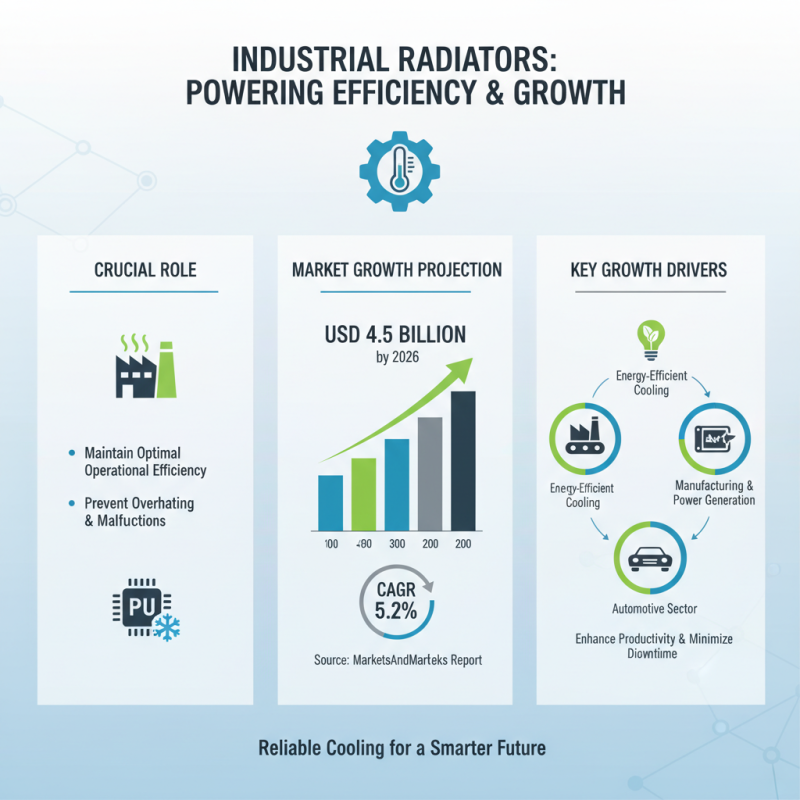

Industrial radiators play a crucial role in maintaining optimal operational efficiency across various industries. According to a report by MarketsandMarkets, the global industrial radiator market is projected to reach USD 4.5 billion by 2026, growing at a CAGR of 5.2%. This growth is driven by the increasing demand for energy-efficient cooling solutions in manufacturing, power generation, and automotive sectors. As businesses strive to enhance productivity and minimize downtime, the selection of the right industrial radiator becomes essential in ensuring that machinery operates within specified temperature ranges, effectively preventing overheating and potential malfunctions.

The significance of industrial radiators extends beyond just temperature control; they are integral to ensuring compliance with safety and environmental regulations. For instance, data from the International Energy Agency indicates that optimizing energy use in industrial processes can yield savings of up to 30%. By choosing efficient radiators that can handle heat load requirements, companies not only improve the performance of their equipment but also contribute to sustainability initiatives. Therefore, a well-informed selection process for industrial radiators not only fulfills operational needs but also aligns with broader corporate responsibility goals, reinforcing the importance of integrating such systems into overall business strategy.

When selecting the right industrial radiators for your business, it is crucial to evaluate the specific heating requirements pertinent to your industry. Different sectors, such as manufacturing, food processing, or pharmaceuticals, have varying needs that influence radiator selection. For instance, a facility that operates machinery generating high heat may require radiators that can efficiently dissipate excess heat while maintaining a stable ambient temperature, thus ensuring optimal operational efficiency and safety.

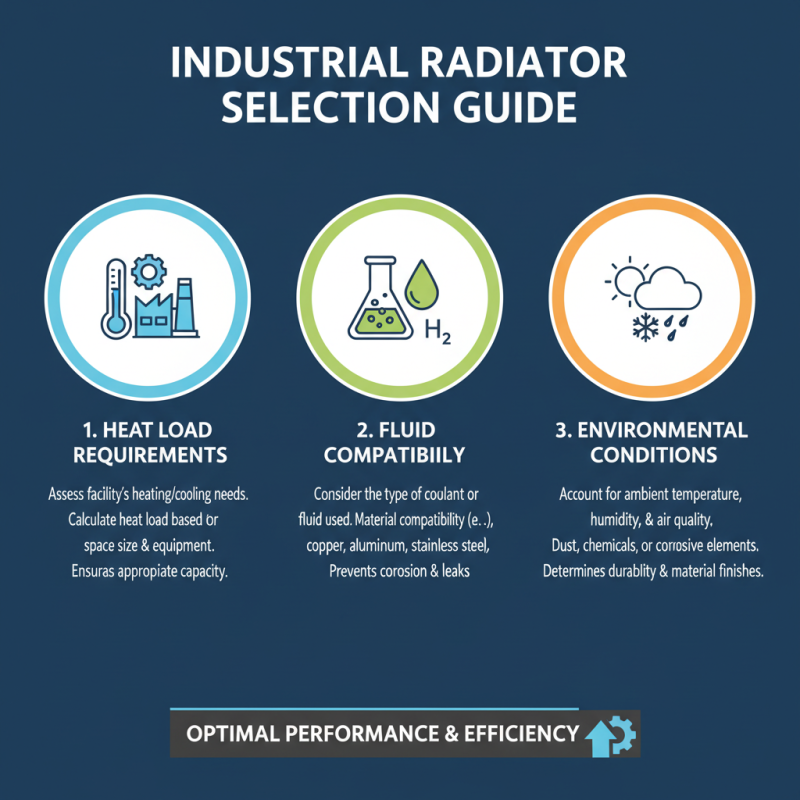

Moreover, factors such as the size of the space, insulation quality, and typical operational temperatures play a significant role in determining the appropriate radiator model. For industries with stringent temperature controls, such as healthcare or laboratory services, choosing radiators that offer precise temperature regulation capabilities can prevent costly downtime and product spoilage. Additionally, considering the type of fluids being heated or cooled is essential, as certain applications may necessitate specialized materials to withstand corrosive environments or extreme pressures. Engaging with industry professionals to analyze these specific heating needs can guide businesses to make informed decisions, ultimately enhancing productivity and ensuring compliance with safety standards.

When selecting the right industrial radiators, understanding the different types available is crucial in meeting your business needs. Primarily, you can categorize industrial radiators into water-cooled and air-cooled types.

Water-cooled radiators are known for their efficiency in heat transfer, utilizing water as a cooling medium. They are often preferred in large-scale operations where space and water availability are not major concerns. Their ability to maintain stable temperatures makes them suitable for heavy machinery and equipment that generates significant heat during operation.

On the other hand, air-cooled radiators commonly use ambient air to dissipate heat. These are beneficial in environments where water supply is limited or expensive. Air-cooled options tend to be more compact and easier to install, making them ideal for smaller facilities or operations with mobility requirements. Additionally, some modern designs incorporate advanced technologies such as finned tubes and enhanced airflow mechanisms to optimize cooling efficiency.

Understanding these fundamental differences will empower businesses to make informed decisions tailored to their specific operational needs and environmental constraints.

When selecting an industrial radiator, several key factors must be taken into consideration to ensure optimal performance and efficiency. First, you should assess the specific heating or cooling needs of your facility. This involves understanding the heat load requirements, which can vary significantly depending on the size of the space and the equipment in use. Proper calculations will help you choose a radiator with the appropriate capacity to maintain the desired temperature levels without unnecessary energy expenditure.

Another critical aspect is the material of the radiator. Different materials, such as aluminum, steel, or copper, have unique thermal conductivity properties and durability levels. The choice of material can greatly affect the radiator's performance and longevity, especially in harsh industrial environments. Additionally, consider the radiator's maintenance requirements. Models that are easy to clean and service can save resources and downtime in the long run. Lastly, ensure that the radiator is compatible with your existing systems, as compatibility with fluid types and connections is essential for seamless integration and optimal operation.

When selecting industrial radiators, budgeting and maintenance considerations are paramount for ensuring longevity and efficiency. Initially, it's essential to define a clear budget that encompasses not just the initial expenditure on the radiators, but also the ongoing operational costs. This means accounting for energy consumption, potential repair costs, and the frequency of necessary replacements. Choosing a radiator with higher initial costs but lower running expenses may ultimately provide better value over time, especially in high-demand industries where operational efficiency significantly impacts the bottom line.

Equally important is establishing a maintenance plan tailored to the specific needs of the industrial radiators selected. Regular maintenance checks can prevent costly breakdowns and extend the lifespan of the equipment. Creating a schedule for inspections and cleaning, and ensuring that staff are trained to recognize issues, can mitigate risks associated with equipment failure. Additionally, businesses should consider the availability of replacement parts and the expertise required for repairs when choosing their radiators, as these factors can influence both short-term operational efficiency and long-term financial planning.