In the realm of thermal management, understanding the intricacies of Heat Exchanger Cost is paramount for companies looking to optimize their operational expenses. According to the latest industry report by Global Market Insights, the heat exchanger market is projected to exceed $20 billion by 2027, driven by the growing demand for energy-efficient systems across various sectors, including chemical processing and HVAC. Industry expert Dr. Alice Johnson, a renowned figure in thermal technology, asserts, "The cost of a heat exchanger can significantly impact overall project budgets, making it imperative for engineers to consider various influencing factors during the selection process."

The calculation of Heat Exchanger Cost is not merely about the purchase price; it encompasses a vast array of factors such as design complexity, material selection, and maintenance requirements. With materials accounting for up to 60% of the total costs, strategic material choices can lead to substantial savings. Furthermore, installation costs and energy efficiency ratings also play a crucial role in determining the final price, influencing both operational efficiency and long-term sustainability. As businesses increasingly seek to mitigate costs while enhancing performance, comprehending these factors becomes essential for informed decision-making in the heat exchanger market.

The cost of raw materials is a critical factor influencing the overall expenses associated with heat exchanger production. The primary materials used in these systems typically include metals like stainless steel, copper, and aluminum, as well as specialized alloys. Fluctuations in the prices of these metals can directly impact the cost of manufacturing, leading to a cascading effect on the final price of heat exchangers. Factors such as global demand, mining output, and geopolitical events can cause significant variations in raw material costs.

Additionally, the cost of energy used in the production process also plays a crucial role. Many manufacturers require substantial energy to transform raw materials into finished products. Changes in energy prices, whether due to policy changes, market demand, or resource availability, can influence production costs, making it essential for manufacturers to closely monitor these variables. Furthermore, the availability of alternative materials and the development of innovative production techniques can also affect material costs, potentially offering cost-saving advantages in specific scenarios. Thus, any company involved in heat exchanger production must stay informed about these influencing factors to maintain competitive pricing and ensure sustainability in operations.

The complexity of heat exchanger design plays a pivotal role in determining overall costs. Intricate designs, which may involve multiple fluid paths and specialized materials, often lead to increased fabrication and assembly time. This added complexity can also necessitate advanced manufacturing techniques, which are typically more expensive than standard processes. Consequently, engineers must find a balance between optimizing performance and managing costs, which can impact the final price of the heat exchanger significantly.

Moreover, the design complexity directly influences other cost factors, such as maintenance and operational efficiency. For example, a more complicated design might require specialized maintenance, leading to higher long-term costs for operators. Additionally, intricate systems may face challenges in heat transfer efficiency, resulting in potential energy losses that further escalate operational expenses. Thus, understanding the relationship between design complexity and costs is essential for stakeholders looking to invest wisely in heat exchanger technology.

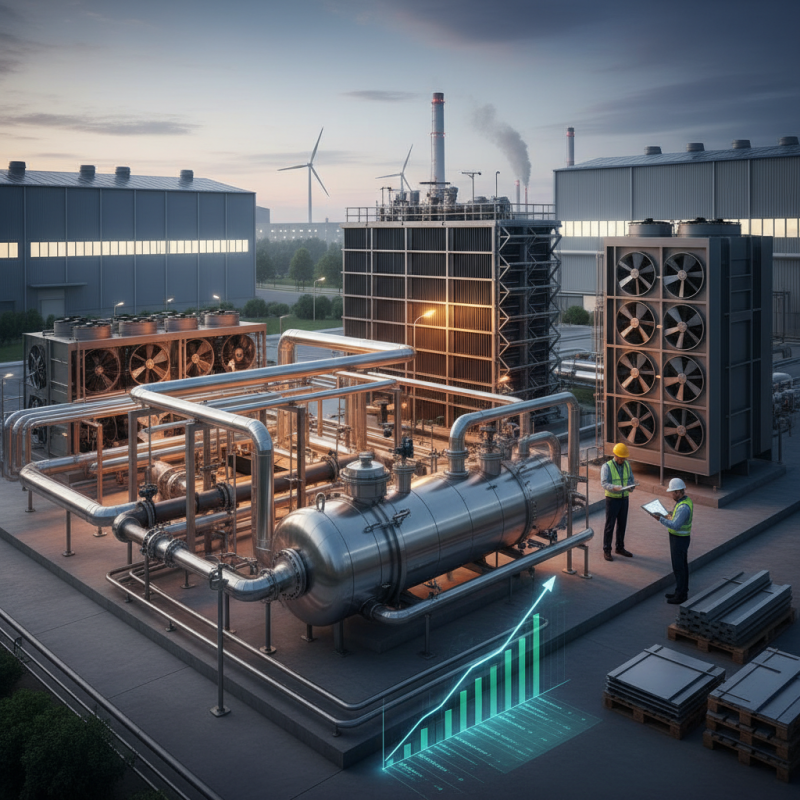

The size and capacity of a heat exchanger are critical factors that significantly influence its pricing. When determining the cost, potential buyers must consider both the physical dimensions and the thermal performance capabilities of the equipment. Larger heat exchangers that can handle higher flow rates and larger temperature differentials often come with a substantial price tag due to the increased material requirements and more complex manufacturing processes involved. The relationship between size and capacity means that a well-designed heat exchanger not only needs to efficiently transfer heat but also maintain structural integrity under varying operating conditions.

The size and capacity of a heat exchanger are critical factors that significantly influence its pricing. When determining the cost, potential buyers must consider both the physical dimensions and the thermal performance capabilities of the equipment. Larger heat exchangers that can handle higher flow rates and larger temperature differentials often come with a substantial price tag due to the increased material requirements and more complex manufacturing processes involved. The relationship between size and capacity means that a well-designed heat exchanger not only needs to efficiently transfer heat but also maintain structural integrity under varying operating conditions.

Moreover, the application of the heat exchanger plays a pivotal role in defining its size and capacity requirements. For instance, industries such as oil and gas, power generation, and chemical processing demand customized solutions that often require larger units capable of handling high volumes and extreme conditions. As a result, these specifications can drive up costs due to the need for advanced engineering and possibly unique materials that resist corrosion or high temperatures. In this context, clients must carefully evaluate their specific needs to ensure that they invest in a heat exchanger that meets their operational demands while balancing budget constraints.

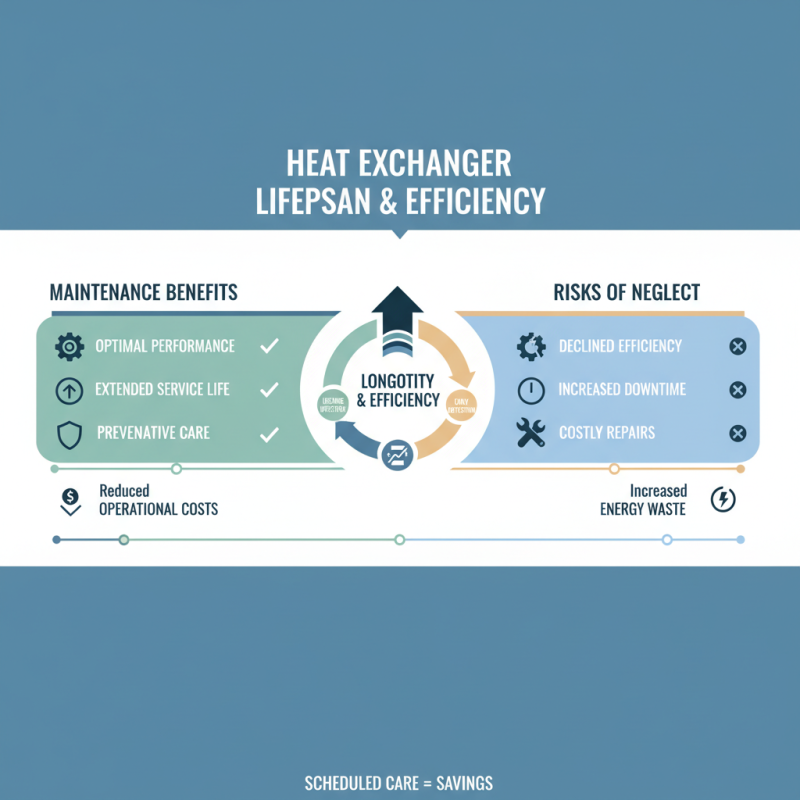

When considering the longevity and efficiency of heat exchangers, the maintenance and operational costs over their lifespan play a crucial role. Regular maintenance not only ensures optimal performance but also helps to extend the service life of the heat exchanger. Neglecting routine checks can lead to a decline in efficiency, resulting in increased operational costs due to energy waste and potential downtimes. Scheduled maintenance, such as cleaning and inspections, can prevent significant issues, allowing for early detection of problems that may escalate into costly repairs.

Moreover, operational costs are influenced by factors such as the type of fluids being exchanged, temperature differentials, and flow rates. For instance, the choice of materials can impact both initial costs and ongoing expenses, as certain materials may require more intensive maintenance or have shorter lifespans. Additionally, energy consumption during operation is a vital consideration; optimizing flow rates and maintaining the heat exchanger's design parameters can lead to significant savings over time. This intricate balance between maintenance routines and operational efficiency ultimately defines the total cost of ownership, making it essential for operators to strategize effectively for long-term financial sustainability.

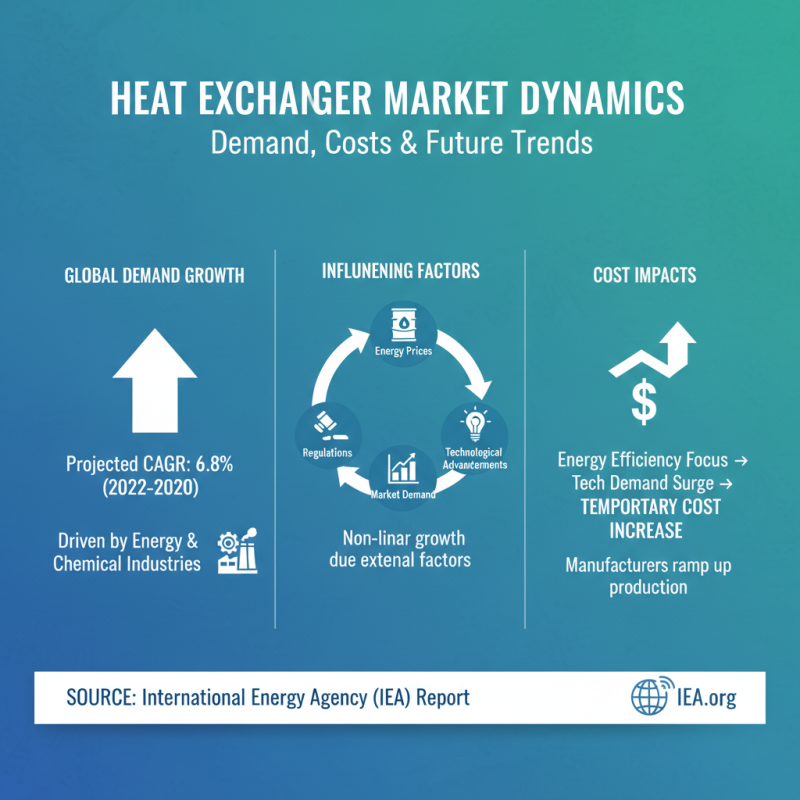

Market demand fluctuations play a significant role in determining the costs associated with heat exchangers. According to a recent report by the International Energy Agency (IEA), the global demand for heat exchangers is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2022 to 2030, primarily driven by the expanding energy and chemical industries. However, this growth is not linear; it is susceptible to various external factors, including changes in energy prices, regulations, and technological advancements. For instance, increased focus on energy efficiency has led to a surge in demand for innovative heat transfer technologies, which can temporarily inflate costs as manufacturers ramp up production to meet new standards.

Furthermore, the cyclic nature of industrial activity directly influences the heat exchanger market. A report from Transparency Market Research highlights that periods of economic downturn can result in decreased investments in infrastructure, leading to lower demand for heat exchangers. Conversely, during economic upturns, industries are more likely to invest heavily in upgrading their systems, thus driving up costs due to heightened competition among manufacturers. Additionally, fluctuations in raw material prices, such as copper and stainless steel, further exacerbate this volatile market. As these materials make up a significant portion of heat exchanger construction, their price changes can have an immediate and impactful effect on the overall cost structure.