The cost of heat exchangers significantly impacts various industries. In 2026, multiple factors will influence heat exchanger cost. Understanding these elements is crucial for manufacturers and buyers alike.

Firstly, material prices will continue to fluctuate. Copper and aluminum are essential for heat exchangers. Their market dynamics will directly affect costs. Labor costs also play a crucial role. Skilled workers are necessary for manufacturing. Additionally, technological advancements may bring new efficiencies but at a price.

External factors also need consideration. Regulations about environmental impacts could lead to higher expenses. Market demand will fluctuate, affecting availability and pricing. As companies adapt, heat exchanger cost will remain a key consideration. It's important to stay informed about these factors. Reflecting on these influences will aid in making strategic decisions.

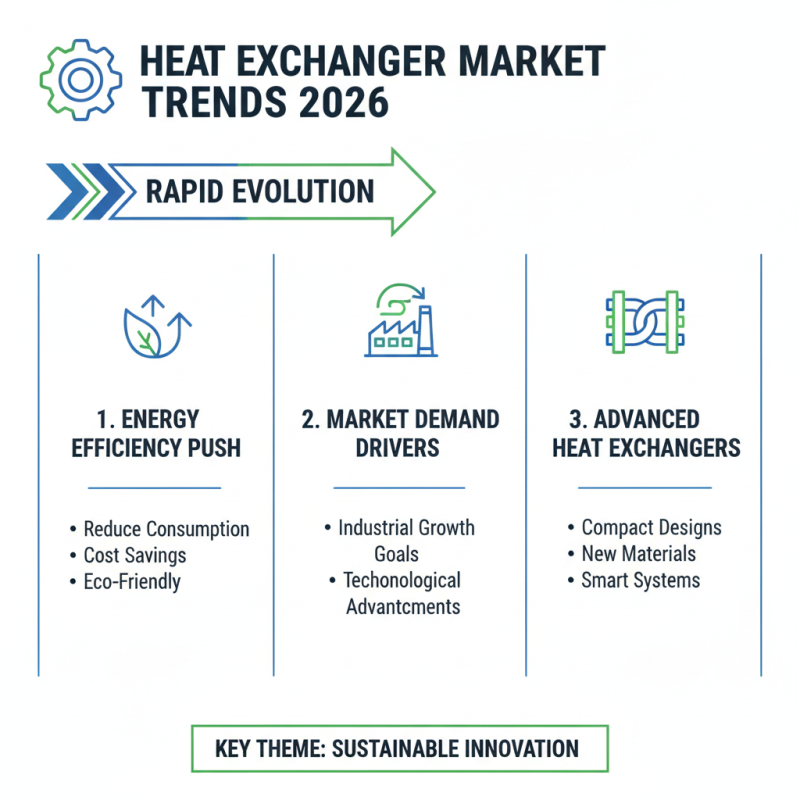

The heat exchanger market is evolving rapidly. Several trends are shaping its demand in 2026. One major factor is the push for energy efficiency. Companies are focusing on reducing energy consumption. This need drives the adoption of advanced heat exchangers.

Another trend is the increasing environmental regulations. Industries are under pressure to minimize emissions. To comply, many are upgrading their systems. They seek better performance and lower environmental impact. This shift in requirements influences the design and selection of heat exchangers.

Additionally, the rise of automation in manufacturing plays a key role. Smart technologies and IoT integration are becoming common. These innovations improve monitoring and maintenance. However, the complexity they bring can be challenging. Industries must rethink their strategies and adapt to these changes. Overall, these trends significantly impact heat exchanger demand, creating both opportunities and obstacles.

The cost of heat exchangers in 2026 will largely hinge on key materials used in production. According to industry reports, copper prices have surged by 15% over the past year, which significantly impacts overall costs. Copper, a primary material in many heat exchangers, is essential for efficient thermal conductivity. The rising demand in construction and technology sectors drives this price increase.

Stainless steel, another critical component, has also seen fluctuations. Recent studies indicate that alloy pricing rose due to global supply chain disruptions. The 2023 rise in nickel prices, which is a key alloying element, has strained budgets for manufacturers. Fabrication challenges alongside these costs can lead to higher end-user prices, leaving some projects underfunded or postponed.

Moreover, alternative materials like titanium are gaining attention, as they offer corrosion resistance. However, titanium is often more expensive to source and process. Reports reflect that while companies aim for durability, they must balance this with cost. With these factors in flux, manufacturers may face tough choices. This evolving landscape invites further reflection on how to meet performance needs within tight budgets.

| Factor | Description | Estimated Impact on Cost (%) |

|---|---|---|

| Raw Material Prices | Fluctuations in the cost of metals and alloys used in heat exchangers. | 25% |

| Technological Advances | Improvements in design and manufacturing technology. | 15% |

| Labor Costs | Changes in wage structures and availability of skilled labor. | 20% |

| Energy Costs | Variations in the cost of energy used during production. | 10% |

| Regulatory Compliance | Costs associated with meeting industry regulations and standards. | 12% |

| Market Demand | Variability in market demand affecting production scale. | 8% |

| Supply Chain Stability | Impact of global supply chain disruptions. | 5% |

| Research and Development | Investment in R&D for innovative product development. | 7% |

| Transportation Costs | Costs related to the distribution of heat exchangers. | 3% |

| Currency Fluctuations | Impact of global currency exchange rates on imported materials. | 5% |

Technological innovations are transforming the heat exchanger market. In 2026, new materials and designs will affect pricing drastically. Lightweight materials are more efficient. They reduce energy consumption and enhance performance. Advanced manufacturing processes also lower production costs. However, these innovations require investment and can drive initial prices up.

Companies should assess new technologies carefully. Innovations in automation can improve manufacturing efficiency. Yet, not all technologies yield immediate returns. Quality control might lag behind, affecting reliability. Evaluating the long-term benefits is essential.

Tips: Focus on collaborations with tech providers. Sharing knowledge can lower costs and risks. Stay updated on market trends. Embrace emerging technologies wisely. Opt for gradual implementation to avoid overwhelming challenges. Understanding the balance between innovation and cost is key.

Regulatory policies play a critical role in shaping heat exchanger expenses. As governments tighten regulations, manufacturers face increased compliance costs. These costs often trickle down to the end-users. Environmental standards are becoming stricter. This impacts the materials and processes used in heat exchanger production. It forces companies to invest in new technologies, which can raise prices.

Keeping an eye on regulations is essential. Companies must adapt to these changing policies. Ignoring them can lead to higher penalties or even production halts. It’s crucial to stay informed about potential regulatory shifts in the industry. Regular reviews of compliance strategies can help manage costs.

Tip: Get involved in industry forums. These platforms often discuss upcoming regulations. They can provide insights and guidance on best practices. Flexibility is key. Adjusting quickly to changes can minimize unexpected expenses. Embracing sustainable practices may not only reduce costs but can enhance brand reputation too.

In 2026, the competitive landscape of heat exchangers will be shaped by several major players. These companies are adapting their strategies to meet market demands. They focus on optimized designs and efficient manufacturing processes. Cost management is crucial for success. Players are investing in technology to lower costs while improving product performance.

The strategies used by these companies vary. Some emphasize research and development to create innovative solutions. Others rely on economies of scale to reduce production expenses. Collaborations with suppliers can also enhance efficiency. However, not all approaches yield a positive outcome. Some firms might struggle with excessive costs or ineffective strategies.

Market shifts impact pricing strategies dramatically. Fluctuations in raw material costs challenge many manufacturers. Companies must stay agile and responsive. While some adapt quickly, others may lag behind. Developing a clear understanding of the market can make all the difference. Despite the challenges, opportunities for growth remain. Companies that refine their strategies will likely prosper.