In 2026, the optimization of heat exchangers plays a vital role in various industries. This is crucial for enhancing energy efficiency and reducing operational costs. According to a recent report by the International Energy Agency, improper management of heat exchanger function can result in a 10-20% increase in energy consumption. This highlights the urgent need for firms to focus on optimizing heat exchanger systems.

Dr. Emily Tan, a leading expert in heat transfer technologies, states, "Understanding heat exchanger function is key to unlocking efficiency in energy-intensive industries." Her insights emphasize the importance of integrating advanced monitoring systems that can improve performance metrics. Despite advancements, many organizations still overlook these essential systems, resulting in wasted energy and financial resources.

As industries push for sustainability, the demand for efficient heat exchangers has surged. Innovations such as enhanced surface technologies and smart controls can significantly improve performance. Yet, many companies fail to adapt quickly, posing potential setbacks. To navigate this evolving landscape, a deeper understanding of how to effectively optimize heat exchanger function is essential.

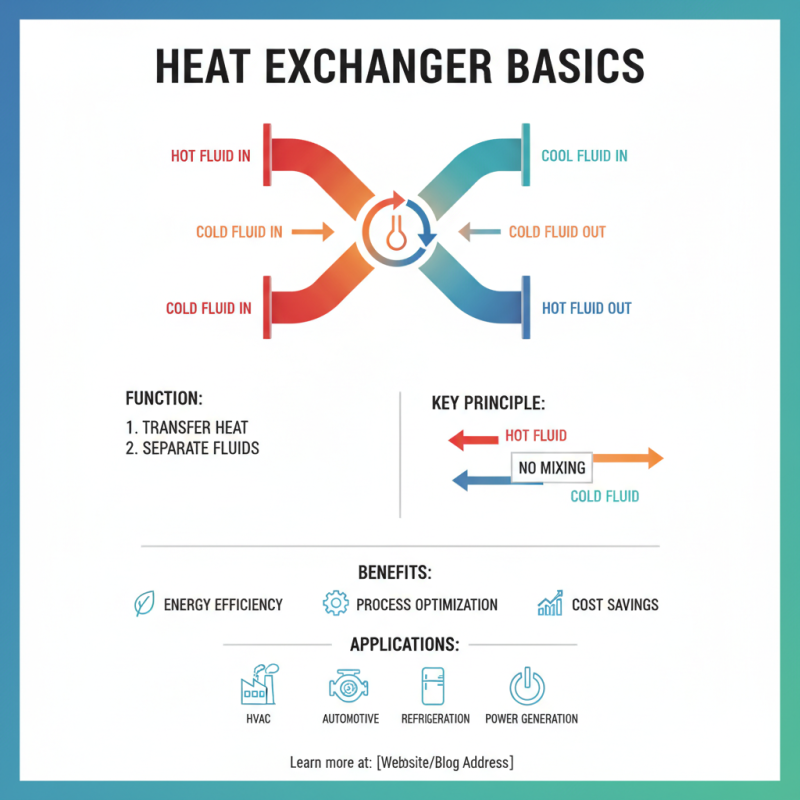

Heat exchangers play a crucial role in various industries. They transfer heat from one fluid to another, enhancing energy efficiency. Understanding how they work is essential for optimization. The basic principle is simple: hot fluid transfers heat to a cooler fluid without mixing. This process can be influenced by several factors.

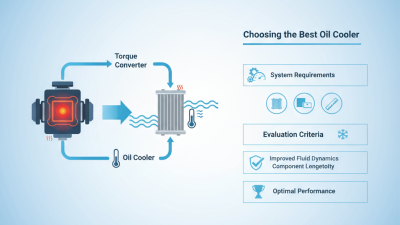

The design of the heat exchanger matters. Different configurations, like shell-and-tube or plate designs, can impact efficiency. For instance, increasing surface area can enhance heat transfer. However, complex designs may lead to higher pressure drops, which could be counterproductive. It's a delicate balance that needs to be carefully considered.

Maintenance is another critical factor. Regular checks help prevent fouling, which impairs performance. However, overzealous maintenance can lead to wear and tear. Finding the right maintenance routine can be challenging. A focus on efficiency requires continuous evaluation and sometimes trial and error. This ongoing process can lead to improved performance and reduced energy consumption.

Heat exchangers play a crucial role in various industries by transferring heat between two or more fluids. There are several types of heat exchangers, each designed for specific applications.

Shell-and-tube exchangers are widely used in oil refineries and chemical plants. They consist of a series of tubes, allowing one fluid to flow through while another surrounds it. This design maximizes heat transfer efficiency.

Plate heat exchangers, on the other hand, are preferred in food processing and HVAC systems. They are compact and efficiently transfer heat through thin plates. However, they can be challenging to clean, which could compromise efficiency.

Air-cooled heat exchangers are essential in power plants and compressor stations, using air to cool fluids. Despite their effectiveness, they require constant maintenance to ensure optimal performance.

Choosing the right type of heat exchanger impacts energy consumption and operational costs. In industries, improper selection may lead to inefficiencies. Understanding the specific needs of each application can greatly improve a system's efficiency. It's an area often overlooked but vital for sustainable operations. Regular assessments and maintenance can uncover hidden inefficiencies that, if addressed, may yield significant improvements.

Heat exchangers play a crucial role in various industries, impacting energy efficiency significantly. In

2026, understanding the factors influencing heat exchanger efficiency is essential. A recent industry report indicates that up to

30% of energy losses in industrial processes can be attributed to inefficient heat exchange. This underlines the need for

continuous monitoring and evaluation of these systems.

Identifying key factors is vital. One significant aspect is the flow arrangement within the heat exchanger.

Crossflow, counterflow, and parallel flow configurations each have distinct efficiency profiles. For instance, research shows that

counterflow systems can achieve up to 30% higher thermal efficiency compared to other designs. Moreover,

fouling, or the accumulation of unwanted material on surfaces, can greatly reduce efficiency, sometimes by more than

50%. Regular maintenance and cleaning protocols must be established.

The material composition also affects performance. Studies suggest that using

advanced materials can improve heat transfer rates. However, the upfront costs might deter implementation. Decisions must balance potential savings

with initial investments. This complexity illustrates the continuous need for assessment and innovation in optimizing heat exchanger efficiency. Uncovering these factors will lead to

more effective and sustainable industrial practices in the years to come.

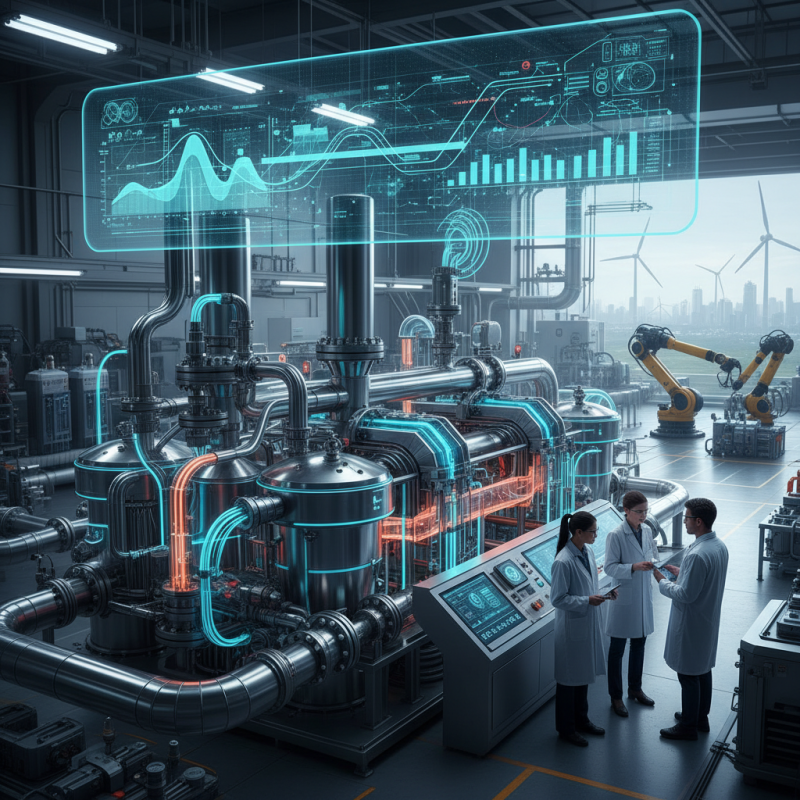

In recent years, advanced technologies have emerged to enhance heat exchanger performance significantly. One approach is using AI-driven analytics. These tools assess real-time data and predict maintenance needs. They help in identifying inefficiencies before they escalate. As a result, downtime is minimized.

Another innovation is the integration of nanotechnology in heat exchanger materials. This leads to improved thermal conductivity. It can also reduce fouling, which affects efficiency over time. By allowing for smoother fluid flow, nanomaterials enhance heat transfer rates.

Tips: Regularly inspect and clean your heat exchangers. Neglect can lead to buildup and reduced efficiency. Implementing real-time monitoring can pinpoint issues early. Small upgrades may drastically improve performance. Always consider how new materials can fit your existing systems. Embrace change, but reflect on past setups. Some older designs may still hold value. Adjustments can lead to significant gains.

| Technology | Efficiency Improvement (%) | Cost Impact (%) | Implementation Time (Months) |

|---|---|---|---|

| Heat Transfer Enhancements | 15 | 5 | 6 |

| Automation & AI Monitoring | 20 | 10 | 12 |

| Advanced Materials | 25 | 15 | 18 |

| Heat Recovery Systems | 30 | 20 | 24 |

| Modular Design | 10 | 8 | 9 |

The future of heat exchanger design is crucial for boosting energy efficiency. Reports indicate that energy losses in traditional systems can reach up to 20%. This is a significant challenge. Improved designs could reduce these losses dramatically. For instance, compact heat exchangers can save space and enhance performance, making them a preferred choice for many applications.

Moreover, emerging materials like graphene and advanced coatings may increase heat transfer efficiency. Research suggests these materials can improve performance by 30%. However, implementation can be costly. Some businesses may hesitate to invest in new technology.

Digital twin technology is another trend gaining traction. It allows real-time monitoring and predictive maintenance. This can increase the lifespan of heat exchangers and minimize downtime. These innovations promise substantial energy savings, but the transition isn't seamless. Organizations must adapt their processes. Balancing costs and benefits is a common struggle in the industry. Achieving high efficiency is possible, but it requires thoughtful consideration and strategic investment.