In the complex world of industrial machinery, maintaining optimal operating temperatures is crucial for efficiency and longevity. Hydraulic cooling systems have emerged as a vital technology to address this need, providing a reliable solution for temperature regulation in hydraulic systems. According to Dr. Emily Hart, a renowned expert in hydraulic engineering, "The effectiveness of a hydraulic cooling system directly impacts the operational performance of hydraulic equipment." Her insights underscore the importance of these systems in ensuring machinery not only operates smoothly but also achieves maximum productivity.

The benefits of hydraulic cooling systems are manifold, ranging from heightened energy efficiency to extended equipment lifespan. By dissipating excess heat generated during hydraulic operations, these systems prevent overheating, thereby reducing wear and tear and minimizing costly downtime. Moreover, with the rising demands for sustainability in industrial practices, hydraulic cooling systems play an essential role in optimizing energy consumption, making them a preferred choice among engineers and operators alike.

As we delve into the top ten benefits of hydraulic cooling systems, it becomes evident that understanding their functionality and advantages is essential for anyone involved in hydraulic operations. Implementing effective cooling solutions is not just about maintaining equipment; it’s about fostering innovation and reliability in today’s competitive industrial landscape.

Hydraulic cooling systems play a crucial role in ensuring the efficient operation of various machinery and equipment across different industries. They are designed to maintain optimal temperatures within hydraulic systems, which can be affected by the heat generated during operation. By managing this heat effectively, hydraulic cooling systems contribute to the longevity and reliability of hydraulic components, minimizing the risk of overheating and subsequent system failures.

Understanding the importance of hydraulic cooling systems extends beyond mere functionality. Proper temperature regulation enhances performance and efficiency, ultimately leading to lower operational costs and reduced downtime. These systems help maintain the viscosity of hydraulic fluids, ensuring that they can effectively transmit power and lubricate moving parts. Furthermore, efficient cooling allows for safer operation, as excessive heat can lead to hazardous conditions. In many cases, a well-designed hydraulic cooling system can result in significant energy savings, reinforcing the value of investing in proper cooling solutions for industrial applications.

Hydraulic cooling systems play a crucial role in enhancing the longevity of equipment through efficient temperature control. According to a report by the International Energy Agency, equipment that operates under optimal temperature conditions can experience a lifespan increase of up to 30%. This is primarily due to the fact that hydraulic systems generate significant heat during operation, which can lead to overheating and subsequent component failure if not properly managed. Effective temperature control not only ensures the smooth operation of hydraulic systems but also reduces the need for frequent repairs and replacements, ultimately lowering operational costs for industries reliant on heavy machinery.

Moreover, research from the Society of Automotive Engineers highlights that maintaining hydraulic fluid within the optimal temperature range can significantly improve the efficiency of hydraulic systems, with reports indicating up to a 15% increase in performance. This enhancement is directly linked to better lubricant properties and reduced wear and tear on critical components. By implementing hydraulic cooling systems, industries can ensure that their machinery operates at peak performance, thereby increasing productivity and reducing downtime caused by equipment failures. The long-term benefits of investing in such cooling solutions are evident, as they contribute significantly to the overall health and efficiency of hydraulic machinery.

Hydraulic cooling systems play a crucial role in enhancing energy efficiency within hydraulic operations. By regulating the temperature of hydraulic fluids, these systems help in maintaining optimal operational performance. According to a recent report by the International Energy Agency (IEA), improved cooling solutions can increase a system's overall efficiency by up to 30%. This reduction in overheating not only prolongs the lifespan of hydraulic components but also minimizes energy consumption, leading to significant cost savings for businesses in the long run.

One key strategy to boost energy efficiency is to routinely monitor fluid temperature and quality. By implementing a regular maintenance schedule, companies can ensure that their hydraulic cooling systems operate at peak performance. A study published in the Journal of Hydraulic Engineering highlighted that maintaining proper fluid levels and utilizing advanced cooling technologies could decrease energy losses during operation substantially. It is recommended that facilities utilize temperature sensors and automated alerts to proactively manage their systems.

Additionally, integrating variable-speed drives (VSDs) can provide further advantages. VSDs adjust motor speeds based on real-time cooling needs, which contributes to energy savings. The U.S. Department of Energy estimates that VSDs can improve system efficiency by 24% in hydraulic applications. By embracing these best practices, enterprises can significantly enhance their hydraulic operations' energy efficiency, fostering a more sustainable and cost-effective approach to industrial processes.

This bar chart illustrates the increased energy efficiency in hydraulic operations by implementing hydraulic cooling systems, representing the percentage of energy savings based on various operational aspects.

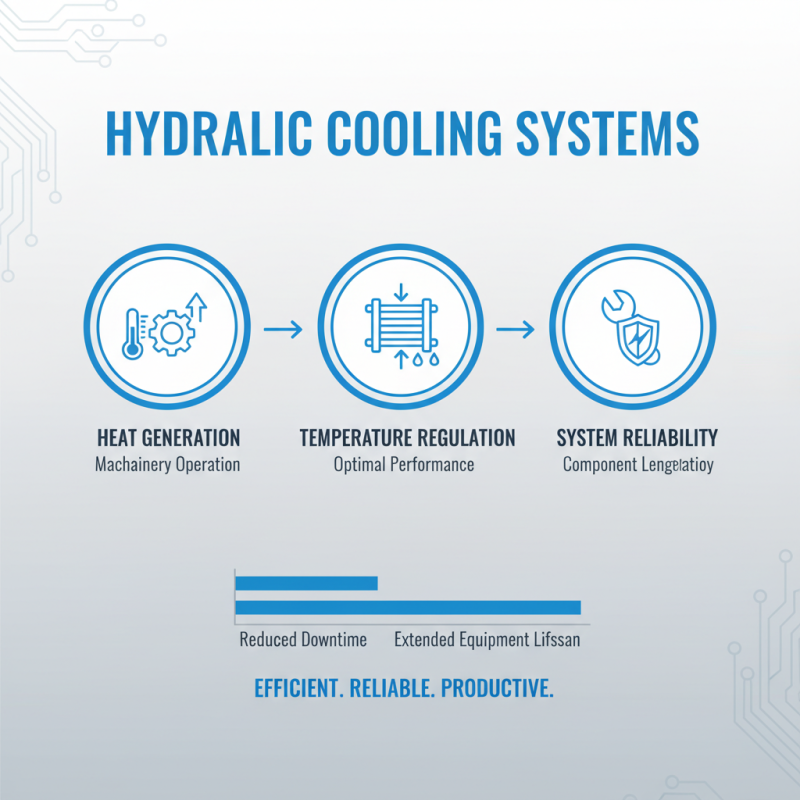

Hydraulic cooling systems are instrumental in optimizing industrial operations, particularly by significantly reducing downtime and maintenance costs. In many industrial processes, machinery generates substantial heat, which can lead to equipment failure if not effectively managed. Hydraulic cooling systems maintain optimal operating temperatures, thus prolonging the lifespan of critical components and preventing unexpected breakdowns. This proactive approach to temperature management allows businesses to schedule maintenance during non-peak hours, minimizing disruption to production.

Furthermore, the integration of hydraulic cooling systems can lead to considerable savings on maintenance expenses. Traditional cooling methods often require frequent manual interventions and repairs, increasing both labor costs and the potential for human error. In contrast, hydraulic systems are designed for reliability and efficiency, often incorporating fail-safe features and automated controls. This automation reduces the need for constant monitoring and allows maintenance teams to focus on other crucial tasks, ultimately enhancing overall operational efficiency. As a result, industries can enjoy uninterrupted production cycles and improved profitability by harnessing the advantages of hydraulic cooling technology.

| Benefit | Description | Impact on Operations | Estimated Cost Reduction (%) |

|---|---|---|---|

| Reduction of Downtime | Minimizes equipment failure and unplanned outages. | Increases operational efficiency. | 20% |

| Lower Maintenance Costs | Reduces frequency of maintenance procedures. | Saves on labor and replacement parts. | 15% |

| Extended Equipment Lifespan | Enhances longevity of machinery by preventing overheating. | Reduces capital expenditure on new equipment. | 25% |

| Improved Safety | Reduces risk of overheating-related incidents. | Fosters a safer workplace environment. | N/A |

| Energy Efficiency | Optimizes energy consumption and reduces utility bills. | Improves overall operational cost-effectiveness. | 10% |

| Enhanced Process Control | Allows for precise temperature management. | Improves product quality and consistency. | N/A |

| Environmental Benefits | Reduces greenhouse gas emissions by optimizing process temperatures. | Promotes sustainable operating practices. | N/A |

| Versatility | Can be applied to various industrial processes. | Increases adaptability of equipment. | N/A |

| Regulatory Compliance | Helps meet industry standards for temperature control. | Avoids fines and legal issues. | N/A |

| Increased Productivity | Boosts overall output by maintaining ideal working conditions. | Enhances profitability through efficient production. | 20% |

Hydraulic cooling systems are increasingly gaining recognition for their environmental benefits, making them a preferable choice in various applications. One significant advantage is their efficiency in reducing energy consumption. By utilizing hydraulic fluid for cooling instead of traditional air systems, these systems can effectively manage heat loads while using less energy. This reduced energy demand translates to lower greenhouse gas emissions, contributing to a more sustainable approach to industrial operations.

Additionally, hydraulic cooling systems contribute to resource conservation and reduced waste. They often have a closed-loop design, which minimizes the need for continuous water supply and helps in conserving this precious resource. Moreover, since they are capable of operating in a range of temperatures and conditions, these systems reduce the need for supplementary cooling resources, further decreasing the environmental footprint. By adopting hydraulic cooling solutions, industries not only enhance their operational efficiency but also align with global efforts to promote sustainability and environmental stewardship.