In the world of automotive performance, the importance of maintaining optimal temperatures in torque converters cannot be overstated. An expert in the field, Dr. Jane Holloway, a leading automotive engineer, once stated, “An efficient Oil Cooler For Torque Converter can significantly enhance performance and prolong the life of your transmission.” This insight underscores the vital role that oil coolers play in managing the heat generated during operation, preventing overheating and ensuring smooth shifting.

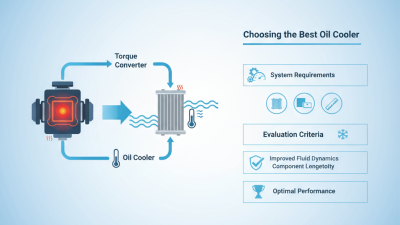

As vehicles are pushed to their limits, especially in high-performance scenarios, the demand for effective cooling solutions becomes paramount. The oil cooler serves as a critical component, allowing the hydraulic fluid to operate within its ideal temperature range. Without proper cooling, torque converters can suffer from reduced efficiency and increased wear, leading to costly repairs and diminished vehicle reliability.

In this discussion, we will explore the top 10 Oil Coolers For Torque Converters available today, evaluating their features, benefits, and suitability for various applications. Each option presents unique advantages, enabling automotive enthusiasts to select the most suitable cooler for their specific needs and ensuring their systems operate at peak performance.

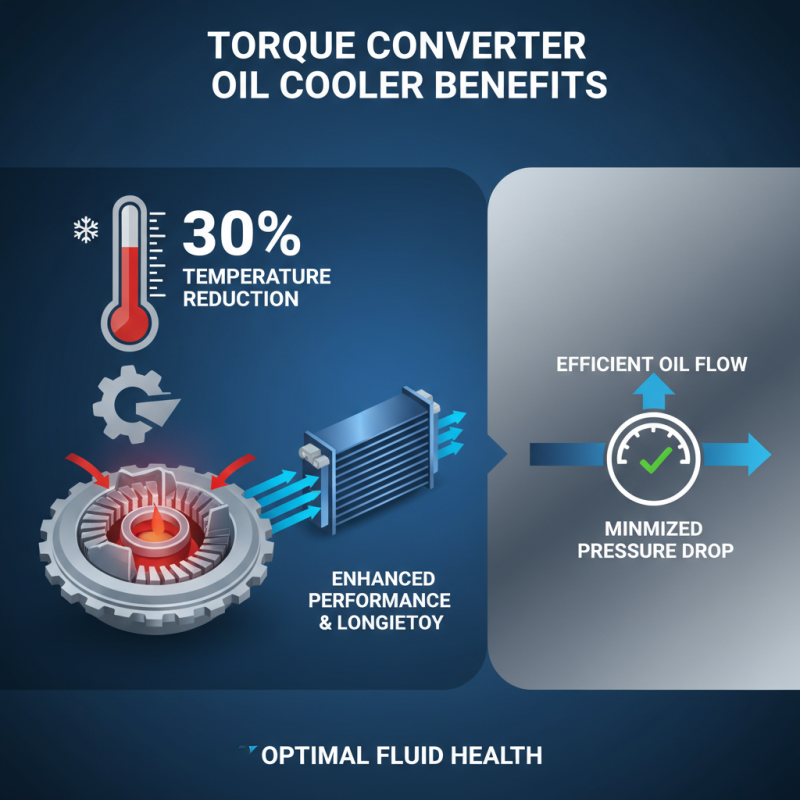

Oil coolers play a crucial role in maintaining the efficiency and longevity of torque converters, which are essential components in vehicles. By regulating the temperature of transmission fluid, oil coolers help prevent overheating, ensuring that the torque converter operates smoothly. High temperatures can lead to fluid breakdown, resulting in reduced performance and potential damage to the components. An effective oil cooler can enhance the hydraulic power transfer, providing better vehicle acceleration and smoother gear shifts.

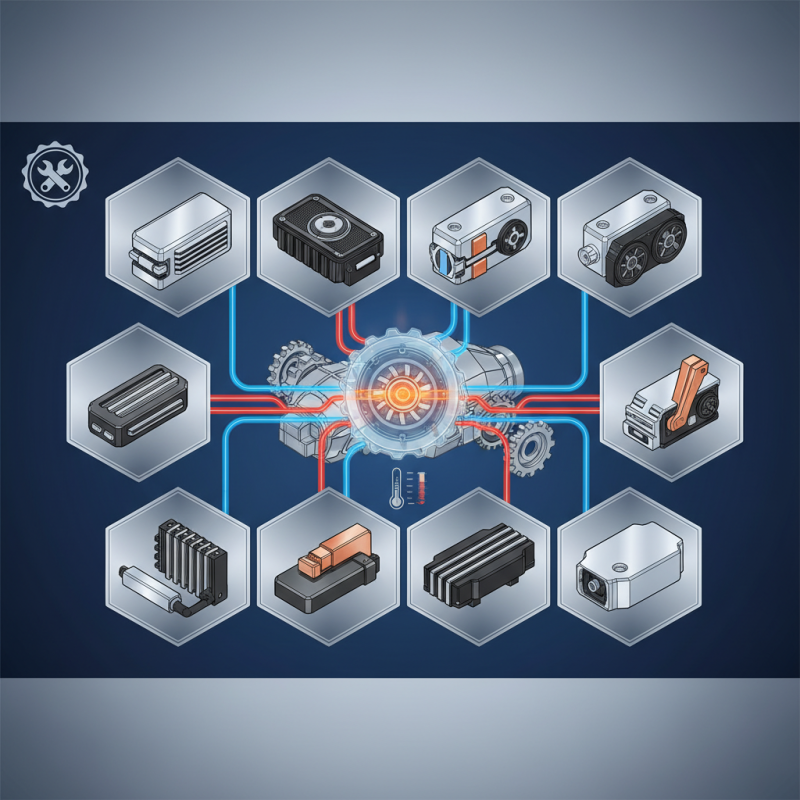

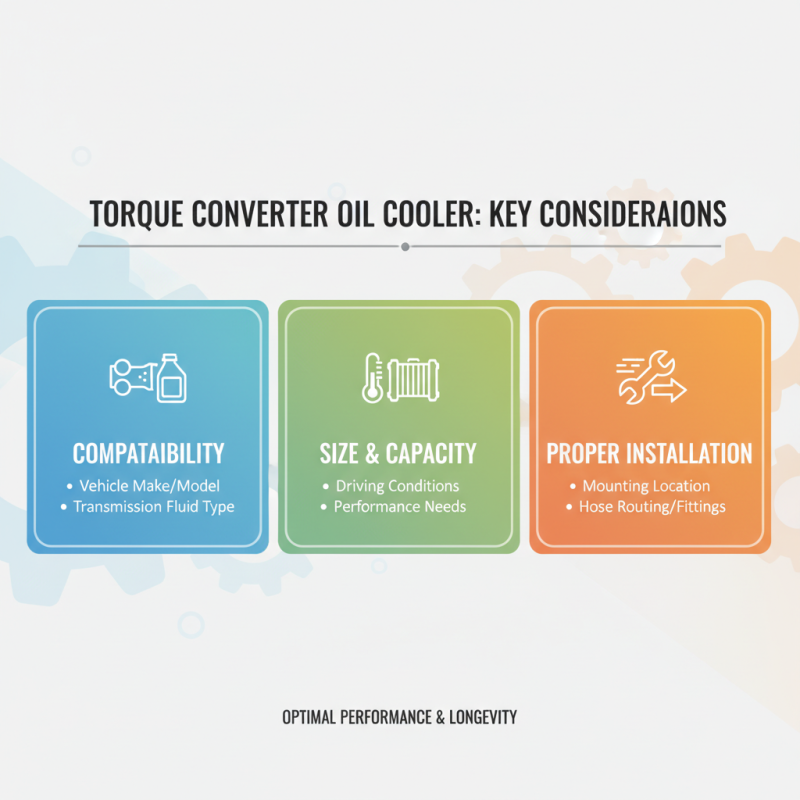

When selecting an oil cooler, it’s important to consider the compatibility with your vehicle's make and model. Additionally, pay attention to the cooler’s size and airflow capacity, as these factors will directly impact its cooling efficiency. Regular maintenance is also vital; ensure the cooler is free from debris and leaks to maintain optimal performance.

Tips for enhancing the effectiveness of your oil cooler:

When considering an oil cooler for torque converters, it's essential to focus on key features that can significantly enhance performance and longevity. One of the primary aspects to look for is the cooler's efficiency in heat dissipation. Research illustrates that effective oil coolers can lower fluid temperatures by up to 30% during operation, which is crucial in preventing overheating and ensuring optimal functionality. Additionally, a well-designed cooler should facilitate efficient oil flow, minimizing pressure drops that can lead to performance loss.

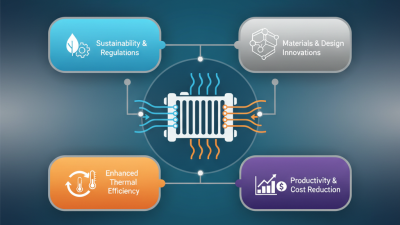

Material construction is another critical factor. High-grade aluminum is often favored for its lightweight and durable properties, while certain models may feature corrosion-resistant coatings. Studies indicate that robust materials can extend the life cycle of coolers, reducing the frequency and costs associated with replacements.

Tips: When selecting an oil cooler, keep an eye on the fin design and core size, as these elements can greatly influence the cooling capacity. It is also beneficial to consider the compatibility of the cooler with your vehicle's overall setup, ensuring it meets the specific thermal demands of your torque converter. Lastly, opt for designs that allow for easy installation and maintenance to enhance user experience and performance.

When choosing an oil cooler for torque converters, understanding the top brands is essential. Leading oil cooler manufacturers prioritize efficiency, durability, and performance to ensure your vehicle operates at its best. Brands known for their advanced technology and innovative designs often feature robust cooling capacities, which help maintain optimal temperatures for your torque converter, ultimately enhancing your driving experience.

Tips: Always consider the compatibility of the cooler with your specific vehicle model. Additionally, look for coolers that offer ease of installation and maintenance, as this can save you time and effort in the long run. An oil cooler should fit seamlessly into your existing system while providing superior cooling performance.

Another key aspect is to assess the materials used in construction. High-quality aluminum alloys are preferred for their lightweight yet strong properties, contributing to effective heat dissipation. Ensure that the cooler you choose meets or exceeds industry standards to guarantee reliability. By focusing on these important factors, you can confidently select a top-notch oil cooler that suits your torque converter needs.

When installing an oil cooler for your torque converter, there are several important considerations to keep in mind to ensure optimal performance and longevity. First, it’s crucial to select a cooler that is compatible with your vehicle's specific make and model, as well as the type of transmission fluid you will be using. This ensures proper cooling efficiency and prevents potential damage to the transmission. Additionally, the size and capacity of the cooler should fit your driving conditions, whether you are tackling normal street driving or pushing the limits in high-performance scenarios.

Another critical aspect is the placement of the oil cooler. It should be installed in a location that allows for unobstructed airflow to maximize cooling efficiency. Typically, this means mounting the cooler in front of the radiator or under the vehicle where there is adequate airflow during driving. Proper hose routing is also essential; ensure that the hoses are long enough to reach the cooler without sharp bends, which could restrict oil flow, and securely fasten all connections to prevent leaks. Lastly, always consider the overall fluid path and how the cooler integrates with the existing cooling system to maintain an effective oil circulation during operation.

Maintaining the performance of your oil cooler is crucial for ensuring the efficient operation of your torque converter. Regularly checking the oil levels and ensuring they meet the manufacturer's specifications is a fundamental step. Insufficient oil can lead to overheating and damage, so it’s essential to top up with the appropriate type. Additionally, inspecting for leaks or cracks in the oil cooler can help prevent potential issues before they escalate. Keeping the cooler clean by removing any debris or buildup will also enhance its efficiency, allowing it to dissipate heat more effectively.

Another important maintenance tip involves monitoring the operating temperature of the oil cooler. Installing a temperature gauge can provide real-time feedback on whether your oil cooler is performing optimally. If the temperatures are consistently higher than normal, it may indicate that the cooler is not functioning as it should or that there may be an obstruction in the system. Upgrading to high-quality oil, which can withstand higher temperatures while offering better lubrication, also plays a significant role in prolonging the life of your oil cooler. Regular maintenance checks and adopting best practices can significantly enhance the performance and longevity of your oil cooler, ensuring your torque converter operates smoothly.