Understanding the function of a heat exchanger is critical across various industries, from power generation to chemical processing and HVAC systems. As Dr. Emily Carter, a leading expert in thermal dynamics and heat transfer, emphasizes, “The efficiency of a system often hinges on the effective design and functionality of its heat exchangers.” This statement underscores the importance of comprehending how heat exchangers contribute to energy conservation, process optimization, and environmental sustainability.

In various applications, heat exchangers serve as pivotal components that facilitate the transfer of heat between two or more fluids while preventing direct contact. Whether in residential heating systems or large-scale industrial operations, the heat exchanger function is essential for maintaining desired temperatures and maximizing energy efficiency. By examining the mechanisms and designs of heat exchangers, we gain valuable insights into their role in enhancing operational performance across a diverse range of sectors.

As industries continue to push for greater efficiency and lower emissions, understanding the heat exchanger function becomes increasingly vital. It not only helps in optimizing existing processes but also informs the development of innovative technologies aimed at meeting future energy demands. This introductory exploration aims to illuminate the fundamental principles of heat exchangers and their significance in a rapidly evolving industrial landscape.

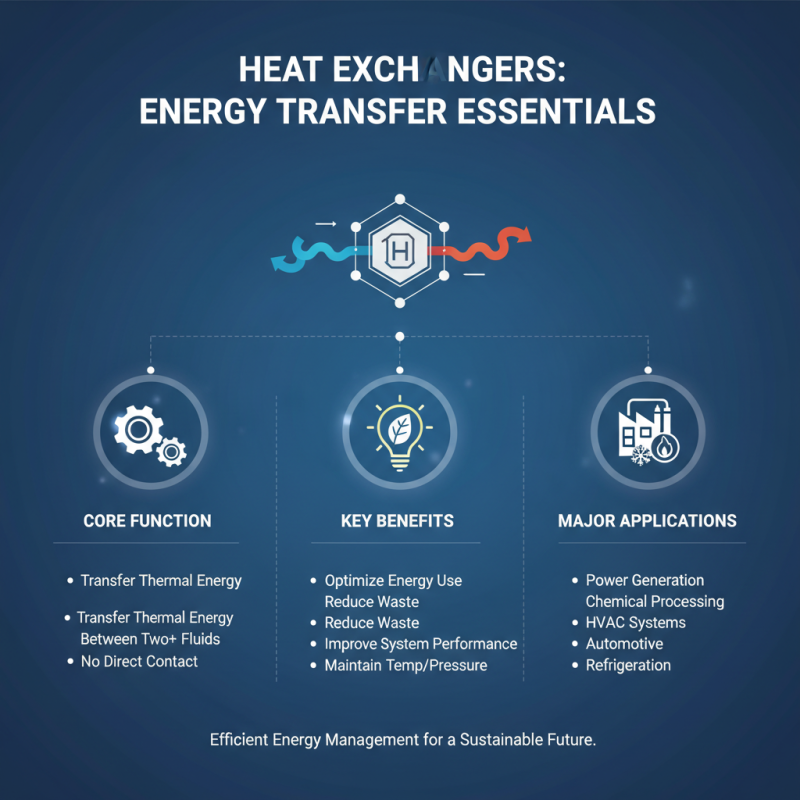

Heat exchangers are critical components in various engineering applications, playing a vital role in the transfer of thermal energy between two or more fluids. These devices facilitate efficient energy management, allowing industries to optimize energy use, reduce waste, and improve overall system performance. In sectors such as power generation, chemical processing, and HVAC systems, heat exchangers help maintain the desired temperature and pressure conditions, significantly enhancing the operational efficiency of equipment and processes.

The importance of heat exchangers extends beyond mere temperature regulation; they are fundamental to safety and sustainability in engineering. By enabling proper heat dissipation, they prevent equipment from overheating, which can lead to catastrophic failures. Furthermore, they contribute to energy conservation efforts by recovering waste heat and reusing it within the system or transferring it elsewhere for use. This characteristic makes heat exchangers not only an engineering necessity but also an essential component in efforts toward sustainable practices in various industries.

Heat exchangers are essential components in a wide range of industrial and domestic applications, designed to transfer heat between two or more fluids without mixing them. Different types of heat exchangers are utilized depending on the specific requirements of the application. One of the most common types is the shell-and-tube heat exchanger, widely used in power plants and chemical processing industries. This configuration consists of a series of tubes, with one fluid flowing through the tubes and another fluid circulating around them in the shell, allowing for effective heat transfer.

Another important type is the plate heat exchanger, which is often found in HVAC systems and food processing applications. It features thin, corrugated plates that create a large surface area for heat transfer while minimizing fluid volume. This design improves efficiency and helps maintain sanitation standards in food production. Furthermore, air-cooled heat exchangers are employed in cooling applications, particularly in petrochemical and refrigeration industries, where ambient air is used to dissipate heat from the process fluid. Each type of heat exchanger is tailored to address specific thermal management challenges, demonstrating their versatility across various sectors.

Heat exchangers are essential components in various applications, facilitating the transfer of thermal energy between two or more fluids. The fundamental principles of heat transfer—conduction, convection, and sometimes radiation—govern the functionality of these devices. In most cases, heat exchangers operate on the basis of conductive heat transfer through solid surfaces, where the temperature difference between the hot and cold fluids drives the heat exchange process. Fluids in close proximity exchange energy without mixing, allowing for efficient thermal regulation in systems ranging from industrial processes to residential heating.

Convection plays a significant role in enhancing the efficiency of heat exchangers, particularly in fluid-based systems. As one fluid absorbs heat, it typically experiences a decrease in density and subsequently rises, while a cooler, denser fluid moves in to replace it, creating a circulation pattern. This convective action not only accelerates heat transfer but also helps maintain a consistent temperature gradient across the heat exchanger. Furthermore, the design and configuration of heat exchangers often optimize these principles, utilizing fins, tubes, or plates to maximize the surface area for heat transfer, ultimately improving overall performance in applications like HVAC systems, chemical processing, and power generation.

Heat exchangers play a crucial role in various industrial applications such as power generation, chemical processing, and HVAC systems. The efficiency and performance of these systems are influenced by several key factors, including temperature differences, flow arrangement, and the properties of the working fluids. According to the U.S. Department of Energy, improving heat exchanger efficiency can lead to energy savings of up to 20% in certain industrial processes, highlighting the importance of understanding these factors for optimal performance.

One critical factor affecting heat exchanger efficiency is the design and arrangement of the heat transfer surfaces. Counterflow configurations are often more efficient than parallel-flow designs due to the larger temperature gradients that can be maintained across the heat exchanger. Additionally, the type of fluid used can significantly impact performance; fluids with higher thermal conductivity will typically transfer heat more efficiently. The choice of materials is also vital, as they must withstand high temperatures and corrosive environments without degrading, thus ensuring longevity and reliability.

Tips: Regular maintenance and cleaning of heat exchangers can prevent fouling, which significantly hampers efficiency. Implementing advanced monitoring technology can also provide real-time data on performance, allowing for timely interventions to maintain optimal operating conditions. Lastly, consider using computational fluid dynamics simulations during the design phase to predict performance and identify possible improvements before installation.

| Application | Type of Heat Exchanger | Efficiency (%) | Key Factors Influencing Performance |

|---|---|---|---|

| HVAC Systems | Plate Heat Exchanger | 85 | Temperature difference, fluid velocity |

| Chemical Processing | Shell and Tube Heat Exchanger | 75 | Heat transfer area, pressure drop |

| Power Generation | Air Cooled Heat Exchanger | 80 | Ambient temperature, airflow |

| Food Processing | Double Tube Heat Exchanger | 90 | Fluid properties, temperature control |

| Petrochemical | Finned Tube Heat Exchanger | 70 | Fluid composition, fouling factors |

Heat exchangers play a crucial role in various industries by facilitating the transfer of heat between two or more fluids. In the oil and gas sector, they are essential for processes such as refining and petrochemical production. By efficiently managing heat transfer, heat exchangers help to optimize energy use, enhance product quality, and maintain safe operating temperatures. This efficiency can lead to significant cost savings and improved environmental performance, making them a vital component of sustainable operations.

In the food and beverage industry, heat exchangers are employed for pasteurization and refrigeration processes. They allow for precise temperature control, ensuring that products are safe for consumption while maintaining their nutritional quality. Additionally, in pharmaceutical manufacturing, heat exchangers are integral for maintaining the correct thermal conditions during production, ultimately contributing to the safety and efficacy of medicines. The versatility of heat exchangers across these industries highlights their importance in improving operational efficiency and ensuring compliance with health and safety regulations.